SAFETY VALVES MANUFACTURER IN INDIA 9881236139

SAFETY VALVES MANUFACTURER

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

Safety valves were first developed for use on steam boilers during the Industrial Revolution. Early boilers operating without them were prone to explosion unless carefully operated.

Vacuum safety valves (or combined pressure/vacuum safety valves) are used to prevent a tank from collapsing while it is being emptied, or when cold rinse water is used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures. When sizing a vacuum safety valve, the calculation method is not defined in any norm, particularly in the hot CIP / cold water scenario, but some manufacturers [1] have developed sizing simulations.

Function and design

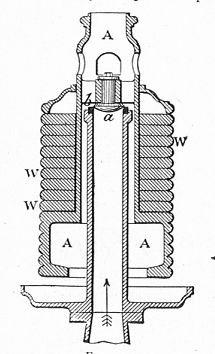

A cross-section of a proportional-safety valve

Safety valves also evolved to protect equipment such as pressure vessels (fired or not) and heat exchangers. The term safety valve should be limited to compressible fluid applications (gas, vapor, or steam).

The two general types of protection encountered in industry are thermal protection and flow protection.

For liquid-packed vessels, thermal relief valves are generally characterized by the relatively small size of the valve necessary to provide protection from excess pressure caused by thermal expansion. In this case a small valve is adequate because most liquids are nearly incompressible, and so a relatively small amount of fluid discharged through the relief valve will produce a substantial reduction in pressure.

Flow protection is characterized by safety valves that are considerably larger than those mounted for thermal protection. They are generally sized for use in situations where significant quantities of gas or high volumes of liquid must be quickly discharged in order to protect the integrity of the vessel or pipeline. This protection can alternatively be achieved by installing a high integrity pressure protection system (HIPPS).

Technical terms

In the petroleum refining, petrochemical, chemical manufacturing, natural gas processing, power generation, food, drinks, cosmetics and pharmaceuticals industries, the term safety valve is associated with the terms pressure relief valve (PRV), pressure safety valve (PSV) and relief valve. The generic term is Pressure relief valve (PRV) or pressure safety valve (PSV) It should be noted that PRVs and PSVs are not the same thing, despite what many people think; the difference is that PSVs have a manual lever to open the valve in case of emergency.- Relief valve (RV): an automatic system that is actuated by the static pressure in a liquid-filled vessel. It specifically opens proportionally with increasing pressure[citation needed].

- Safety valve (SV): an automatic system that relieves the static pressure on a gas. It usually opens completely, accompanied by a popping sound[citation needed].

- Safety relief valve (SRV): an automatic system that relieves by static pressure on both gas and liquid.[2]

- Pilot-operated safety relief valve (POSRV): an automatic system that relieves on remote command from a pilot, to which the static pressure (from equipment to protect) is connected[clarification needed].

- Low pressure safety valve (LPSV): an automatic system that relieves static pressure on a gas. Used when the difference between the vessel pressure and the ambient atmospheric pressure is small.

- Vacuum pressure safety valve (VPSV): an automatic system that relieves static pressure on a gas. Used when the pressure difference between the vessel pressure and the ambient pressure is small, negative and near to atmospheric pressure.

- Low and vacuum pressure safety valve (LVPSV): an automatic system that relieves static pressure on a gas. Used when the pressure difference is small, negative or positive and near to atmospheric pressure.

Legal and code requirements in industry

In most countries, industries are legally required to protect pressure vessels and other equipment by using relief valves. Also, in most countries, equipment design codes such as those provided by the ASME, API and other organizations like ISO (ISO 4126) must be complied with. These codes include design standards for relief valves and schedules for periodic inspection and testing after valves have been removed by the company engineer.[3][4]Today, the food, drinks, cosmetics, pharmaceuticals and fine chemicals industries call for hygienic safety valves, fully drainable and Cleanable-In-Place. Most are made of stainless steel; the hygienic norms are mainly 3A in the USA and EHEDG in Europe.

Development of the safety valve

Deadweight lever valves

lever arm safety valve

Lever arm safety valve in district heating substation before the renovation. Budapest

When used on locomotives, these valves would rattle and leak, releasing near-continuous puffs of waste steam.

Direct-acting deadweight valves

Deadweight safety valve (1909).

Although deadweight safety valves had a short lifetime on steam locomotives, they remained in use on stationary boilers for as long as steam power remained.[11]

Direct spring valves

Locomotive Planet (1830), with a brass-cased direct spring valve

These direct-acting spring valves could be adjusted by tightening the nuts retaining the spring. To avoid tampering, they were often shrouded in tall brass casings which also vented the steam away from the locomotive crew.

Salter spring balance valves

Salter spring balance

The spring balance valve also acted as a pressure gauge. This was useful as previous pressure gauges were unwieldy mercury manometers and the Bourdon gauge had yet to be invented.[15]

Lockable valves

Phoenix (1840) with two sets of Salter spring balance valves

Paired spring balance valves

Midland Spinner, showing paired spring-balance safety valves behind the dome

Paired spring-balance safety valves of a ČSD Class 252.0, with hand adjustment wheels

Ramsbottom safety valves

Ramsbottom valves on a model traction engine

U-shaped Ramsbottom safety valve

Various forms of Ramsbottom valve were produced. Some were separate fittings to the boiler, through separate penetrations.[23] Others were contained in a U-shaped housing fastened to a single opening in the boiler shell. As boiler diameter increased, some forms were even set inside the boiler shell, with the springs housed in a recess inside and only the valves and balance lever protruding outside.[23] These had obvious drawbacks for easy maintenance.

- GB 1299 1299: 7 June 1855: Safety valves, feeding apparatus for steam-boilers.

Naylor valves were introduced around 1866. A bellcrank arrangement reduced the strain (percentage extension) of the spring, thus maintaining a more constant force.[note 1] They were used by the L&Y & NER.[26]

"Pop" valves

Ross pop valve, from Tornado

Cover of The Pop Valve, a self-published magazine by the American army Transportation Corps stationed in France in WWI

These valves coincided with a change in firing behaviour. Rather than demonstrating their virility by always showing a feather at the valve, firemen now tried to avoid noisy blowing off, especially around stations or under the large roof of a major station. This was mostly at the behest of stationmasters, but firemen also realised that any blowing off through a pop valve wasted several pounds of boiler pressure; estimated at 20 psi lost and 16 lbs or more of shovelled coal.[note 2][12]

Pop valves derived from Adams's patent design of 1873, with an extended lip. R L Ross's valves were patented in 1902 & 1904. They were more popular in America at first, but widespread from 1920s.[27]

GWR safety valve cover

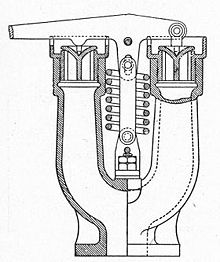

Marine and Cockburn high-lift safety valves

Developments in high-pressure water-tube boilers for marine use placed more demands on safety valves. Valves of greater capacity were required, to vent safely the high steam-generating capacity of these large boilers.[28] As the force on their valves increased, the issue of the spring's increasing stiffness as its load increased (like the Naylor valve) became more critical.[29] The need to reduced valve feathering became even more important with high-pressure boilers, as this represented both a loss of distilled feedwater and also a scouring of the valve seats, leading to wear.[28]High-lift safety valves are direct-loaded spring types, although the spring does not bear directly on the valve, but on a guide-rod valve stem. The valve is beneath the base of the stem, the spring rests on a flange some height above this. The increased space between the valve itself and the spring seat allows the valve to lift higher, further clear of the seat. This gives a steam flow through the valve equivalent to a valve one and a half or twice as large (depending on detail design).[29]

The Cockburn Improved High Lift design has similar features to the Ross pop type. The exhaust steam is partially trapped on its way out and acts on the base of the spring seat, increasing the lift force on the valve and holding the valve further open.[29]

To optimise the flow through a given diameter of valve, the full-bore design is used. This has a servo action, where steam through a narrow control passage is allowed though if it passes a small control valve. This steam is then not exhausted, but is passed to a piston that is used to open the main valve.[28]

There are safety valves known as PSV's and can be connected to pressure gauges (usually with a 1/2" BSP fitting). These allow a resistance of pressure to be applied to limit the pressure forced on the gauge tube, resulting in prevention of over pressurisation. the matter that has been injected into the gauge, if over pressurised, will be diverted through a pipe in the safety valve, and shall be driven away from the gauge.

Types

Steam locomotive No. 46229, Duchess of Hamilton lifts her boiler safety valve after hauling the Welsh Marches Pullman charter.

United States

- ASME (American Society of Mechanical Engineers) Boiler & Pressure Vessel Code, Section I

- ASME (American Society of Mechanical Engineers) Boiler & Pressure Vessel Code, Section VIII, Division 1

- API (American Petroleum Institute) Recommended Practice 520 and API Standard 526, API Standard 2000 (low pressure - Storage tank)

European Union

European standard steam boiler safety valve

- ISO 4126 (harmonized with European Union directives)[30]

- EN 764-7 (former CEN standard, harmonized with European Union directives, replaced with EN ISO 4126-1)

- AD Merkblatt (German)

- PED 97/23/CE (Pressure Equipment Directive - European Union)[31]

Water heaters

Temperature and Pressure safety valve on a water heater.

Pressure cookers

Pressure cookers are cooking pots with a pressure-proof lid. Cooking at pressure allows the temperature to rise above the normal boiling point of water (100 degrees Celsius at sea level), which speeds up the cooking and makes it more thorough.Pressure cookers usually have two safety valves to prevent explosions. On older designs, one is a nozzle upon which a weight sits. The other is a sealed rubber grommet which is ejected in a controlled explosion if the first valve gets blocked. On newer generation pressure cookers, if the steam vent gets blocked, a safety spring will eject excess pressure and if that fails, the gasket will expand and release excess pressure downwards between the lid and the pan. Also, newer generation pressure cookers have a safety interlock which locks the lid when internal pressure exceeds atmospheric pressure, to prevent accidents from a sudden release of very hot steam, food and liquid, which would happen if the lid were to be removed when the pan is still slightly pressurised inside (however, the lid will be very hard or impossible to open when the pan is still pressurised).

The term safety valve is also used metaphorically.

Refrences -

https://en.wikipedia.org/wiki/Safety_valve

Comments